Respirator Safety Training

Learn proper respirator selection, inspection, fit, maintenance, and OSHA 1910.134 compliance for safe work in hazardous environments.

Stay Connected With Us

Respirator Safety Training

Understand how respiratory protection programs prevent exposure to harmful dust, fumes, gases, and biological hazards in industrial settings.

Respirator Safety

Training that helps workers select, fit, and use respirators correctly to protect against dust, fumes, gases, vapors, and oxygen-deficient conditions while maintaining OSHA compliance.

Popular Respirator Safety Courses

Respiratory Protection Awareness

Introduces basic OSHA respiratory protection requirements for workers exposed to airborne hazards.

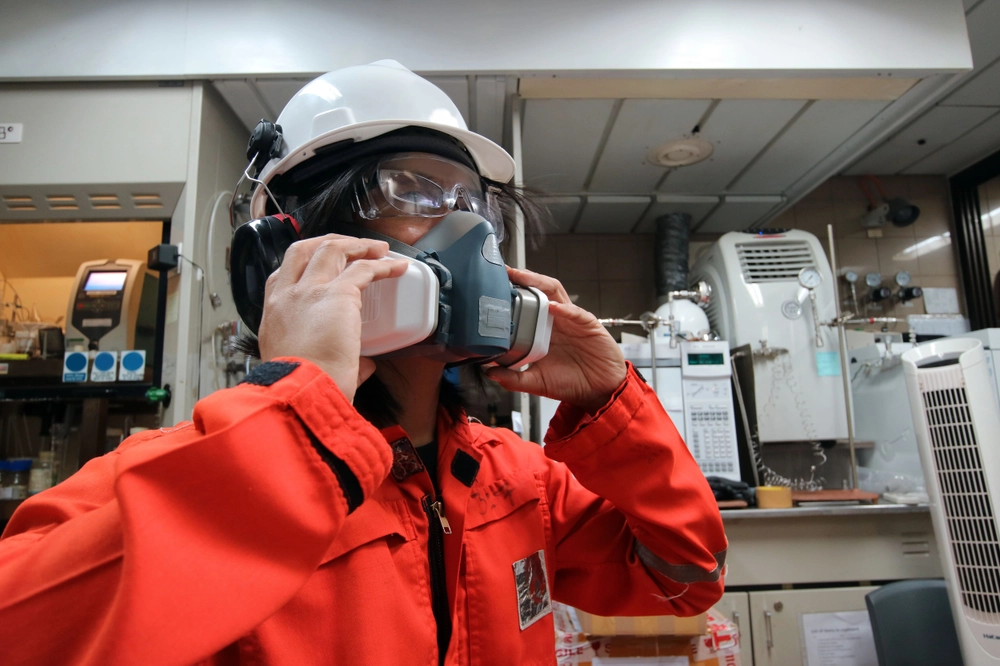

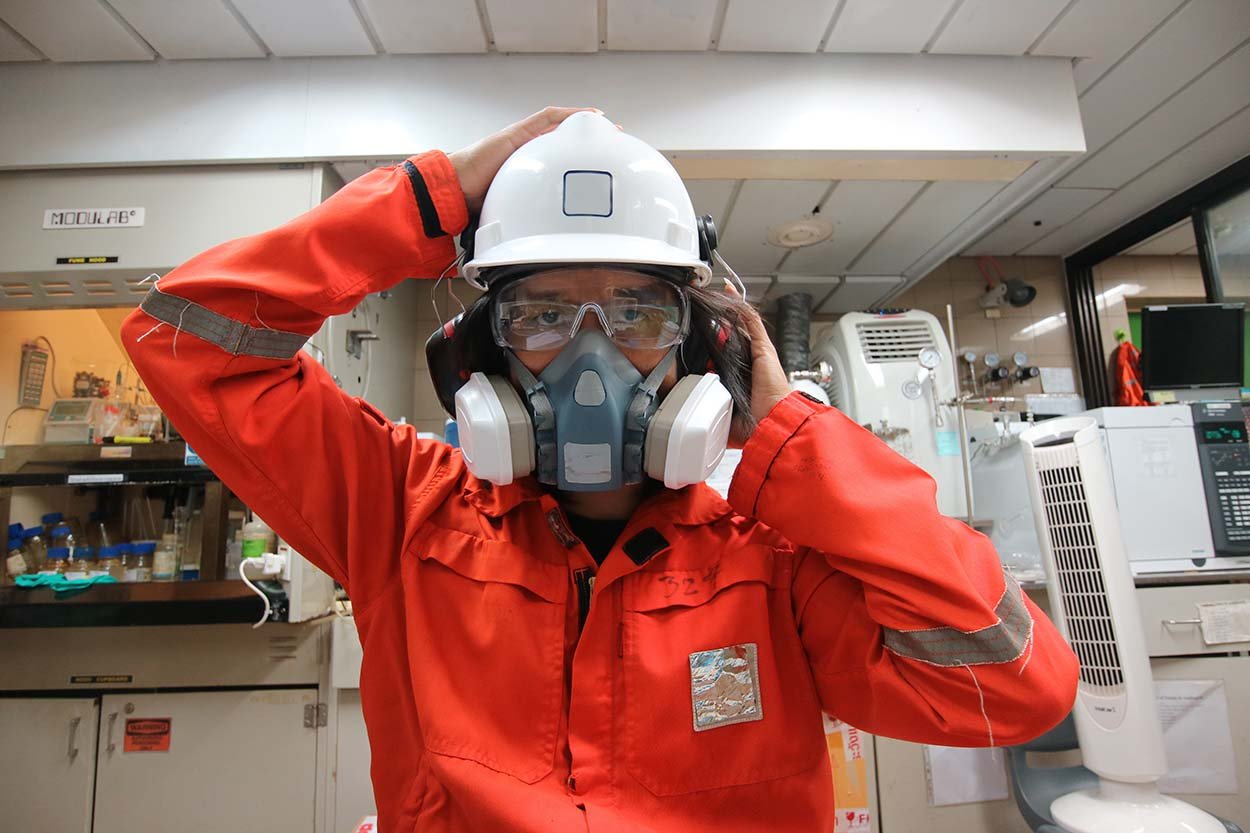

- Types of Respirators & Uses

- Proper Donning & Doffing

- Medical Evaluation Overview

Fit Testing & Program Management

Focused on supervisors and safety officers managing workplace respirator programs.

- Qualitative & Quantitative Fit Testing

- Program Documentation

- Recordkeeping & Evaluation

Advanced Respirator Safety Training

Detailed instruction on air-supplying and filtering respirators for hazardous job sites.

- Air-Purifying vs. SCBA Systems

- Maintenance & Filter Replacement

- Emergency Use Procedures

Partner with Renew Safety

Get answers to common questions about respirator safety and OSHA compliance.

Respirator safety training teaches workers how to properly select, use, and maintain respirators to protect against harmful airborne particles, gases, and vapors.

Any employee required to wear a respirator under OSHA standards—such as those in construction, manufacturing, or healthcare—must complete this training.

Fit testing must be conducted at least annually, or whenever a worker’s facial structure changes, to ensure a proper seal and protection.

Training covers N95, half-mask, full-face, powered air-purifying (PAPR), and supplied-air respirators.

Yes. OSHA-compliant online courses provide interactive instruction and certification for awareness and refresher levels.